Home » Application » Batteries For Medical Devices » Drug Delivery Systems Batteries

The Precise, Unfailing Power Behind Every Dose

Hanery is a leading B2B manufacturer of high-reliability, safety-critical polymer lithium-ion batteries for drug delivery systems. From ambulatory infusion pumps to smart insulin pumps and auto-injectors, we engineer the flawless power source that patients and clinicians rely on for accurate, life-sustaining therapy.

Safety

Low Self-Discharge

Long Lifespan

Lightweight

Your Expert Drug Delivery Battery Manufacturer in China

For devices where power consistency is a matter of health, partner with a manufacturer that prioritizes precision and reliability above all else.

Mission-Critical Reliability

Engineered and manufactured under a zero-tolerance quality policy for flawless, predictable performance.

Stable Voltage Discharge

Our batteries provide a stable voltage platform, ensuring precise motor control and accurate dosage delivery.

Compact & Lightweight Design

Maximizing energy density to create smaller, lighter devices that improve patient mobility and comfort.

Medical-Grade Safety & Certifications

Designed to meet the stringent requirements of IEC 60601-1 and IEC 62133 for patient-critical devices.

Clean & Controlled Manufacturing

Our batteries are produced in a controlled environment to ensure the highest levels of purity and consistency.

Long Shelf Life

Low self-discharge chemistry ensures the battery is ready to perform even after extended storage.

Custom Drug Delivery Batteries as Your B2B Supplier

Hanery is your strategic partner for custom polymer battery packs, meticulously engineered for the life-sustaining field of drug delivery. We understand that in this application, the battery is an active component of a therapeutic system. Our expertise lies in a rigorous, risk-management-based design process, creating supremely reliable and stable power sources that ensure every dose is delivered exactly as prescribed, every time.

Wholesale Drug Delivery Battery Capabilities

We provide custom power solutions for a wide spectrum of therapeutic delivery devices.

Medtronic Drug Delivery Batteries

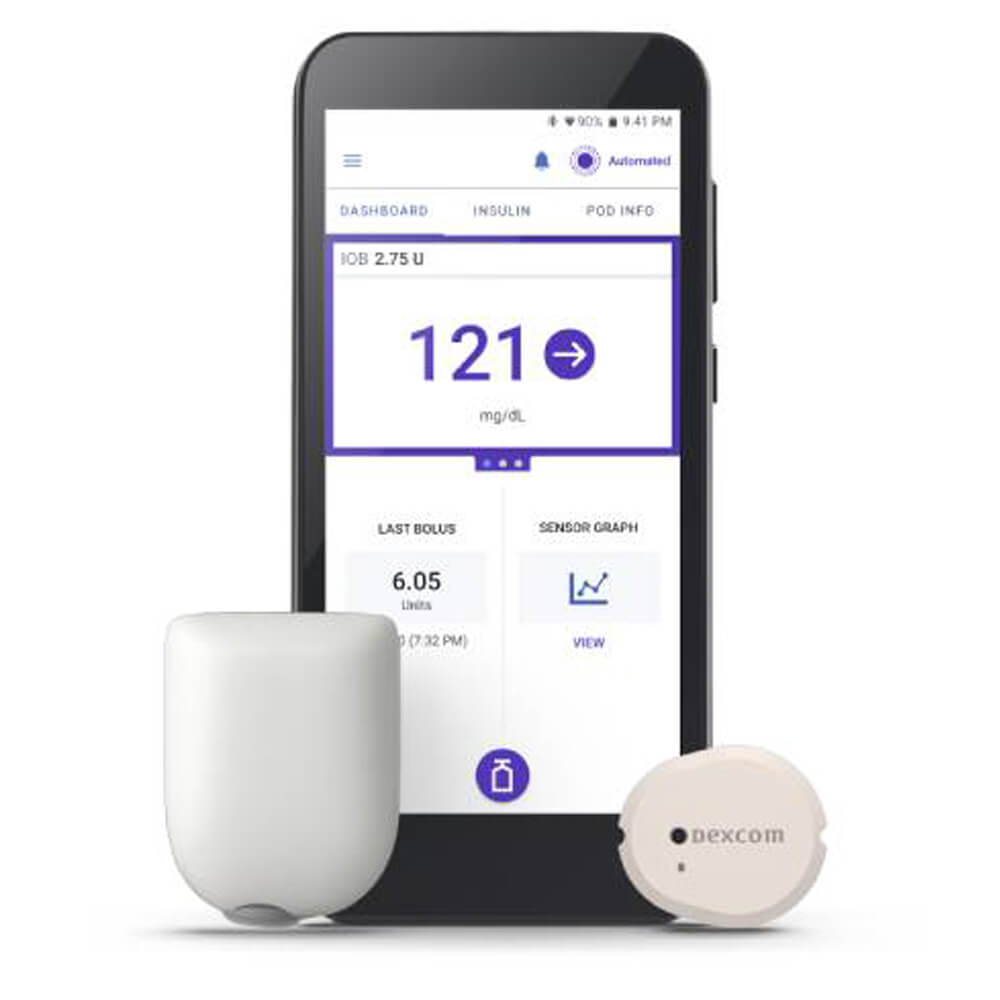

Insulet Drug Delivery Batteries

Tandem Diabetes Care Drug Delivery Batteries

Baxter International Drug Delivery Batteries

Is Unstable Voltage Affecting Your Device's Dosing Accuracy?

Our batteries are engineered for a flat, stable discharge curve, providing the consistent power that precision medical devices demand.

Customized Options for Your Drug Delivery Batteries

We engineer every detail for therapeutic precision and patient safety.

Stable Discharge Chemistry

We select cell chemistries that offer a flat voltage profile to ensure consistent motor and pump performance.

Intelligent BMS with Safety Redundancy

We integrate smart BMS with multiple, redundant safety features and alarms for critical fault conditions.

Custom Form Factors for Portability

We design batteries in unique shapes and sizes to fit into compact, ergonomic, and wearable device housings.

High-Reliability Construction

We use advanced welding techniques and robust internal construction to withstand the rigors of daily use.

Low Self-Discharge Formulation

Ideal for devices that may be stored in emergency kits or used intermittently.

Full Traceability & Documentation

Every pack is serialized and supported by comprehensive documentation for your quality system and regulatory files.

Get Your Batteries in Bulk, Step-by-Step

In-Depth Consultation & FMEA

We start with your device's power profile, use case, and conduct a Failure Mode and Effects Analysis (FMEA).

System Design & DHF Support

We provide a comprehensive proposal with 3D models and documentation to support your Design History File (DHF).

Prototyping & V&V Testing

We produce highly reliable prototypes for your Design Verification and Validation (V&V) testing.

Certification Management & Approval

We manage the entire IEC 62133 and UN38.3 certification process and receive your final approval.

Controlled Mass Production

Your bulk order is manufactured under zero-defect principles, with 100% end-of-line testing.

Global Logistics & Lot Traceability

We manage the compliant shipping process, ensuring full lot traceability for every delivery.

FAQ for Drug Delivery System Batteries

A: We employ a multi-layered strategy: using only premium, medical-grade cells, implementing redundant safety features in our BMS, a rigorous FMEA design process, and 100% comprehensive functional testing on every battery pack.

A: Yes, this is a core competency. We can design ultra-thin, custom-shaped batteries that fit within the discreet, body-worn enclosures of patch pumps and large volume injectors.

A: Due to the extensive engineering, validation, and documentation required for this critical application, our MOQ typically starts at 50,000 to 100,000 units.

A: We select specific lithium-ion chemistries (like LFP or specific NCM blends) known for their flat discharge curves. The integrated BMS also plays a role in managing a stable power output.

A: We provide a full documentation package, including detailed specifications, manufacturing process controls, complete traceability records, and all required safety certifications (IEC 62133, UN38.3) to support your technical file.

A: Our intelligent BMS is designed to safely manage fault conditions. Depending on the fault, it can disconnect the power, trigger an alarm signal to the host device, and prevent any unsafe operation, such as charging in extreme temperatures.

A: Our batteries are designed with very low self-discharge rates. We can provide real-world data and storage guidelines to ensure they meet your product’s required shelf life, often multiple years.

A: While our expertise is in rechargeable (secondary) batteries, we can design the system with a primary (non-rechargeable) cell if your application requires it. More commonly, we can design a rechargeable battery within a device that is intended for single patient use.

A: Given the critical nature and rigorous design process, the lead time for the first batch of prototypes is typically 6-8 weeks.

A: Please provide your device’s power requirements (voltage, capacity, current profile), dimensional constraints, required certifications, the class of your medical device, and any specific reliability or safety targets.