Home » Application » Batteries For Medical Devices » Handheld Diagnostic Instruments Batteries

The Power of Instant Diagnostics, in Your Hand

Hanery is a leading B2B manufacturer of high-energy-density, compact, and reliable polymer lithium-ion batteries for handheld diagnostic instruments. From portable ultrasound systems to point-of-care blood analyzers, we engineer the robust power that enables faster, more accessible, and accurate diagnostics anywhere.

Safety

Low Self-Discharge

Long Lifespan

Lightweight

Your Expert Handheld Diagnostic Battery Manufacturer in China

For instruments that bring the lab to the patient, partner with a battery manufacturer that understands the need for portable, powerful, and reliable energy.

High Energy Density

We maximize mAh capacity in a minimal footprint, enabling smaller, lighter, and more ergonomic instrument designs.

Stable Power Output

Engineered to provide consistent, stable power for sensitive sensors, processors, and high-resolution displays.

Fast Charging Capability

Our batteries can be designed for fast-charging protocols, minimizing downtime in busy clinical settings.

Medical-Grade Safety & Reliability

Designed and manufactured to meet the stringent safety and quality requirements of the medical industry.

Long Service Life

High cycle life ensures the battery lasts for years of demanding daily use, lowering the total cost of ownership.

Full Lot Traceability

We provide complete component and lot traceability, essential for medical device quality management.

Custom Handheld Diagnostic Batteries as Your B2B Supplier

Hanery is your strategic partner for custom polymer battery packs, meticulously engineered for the rapidly growing field of handheld diagnostics. We understand that these devices must be both powerful and portable, delivering lab-quality results in the palm of a hand. Our expertise lies in creating space-optimized, high-density battery systems that provide the long-lasting, stable power needed to drive complex diagnostics, shift after shift.

Wholesale Handheld Diagnostic Battery Capabilities

We provide custom power solutions for a wide spectrum of point-of-care diagnostic devices.

Butterfly Network Handheld Diagnostic Instruments Batteries

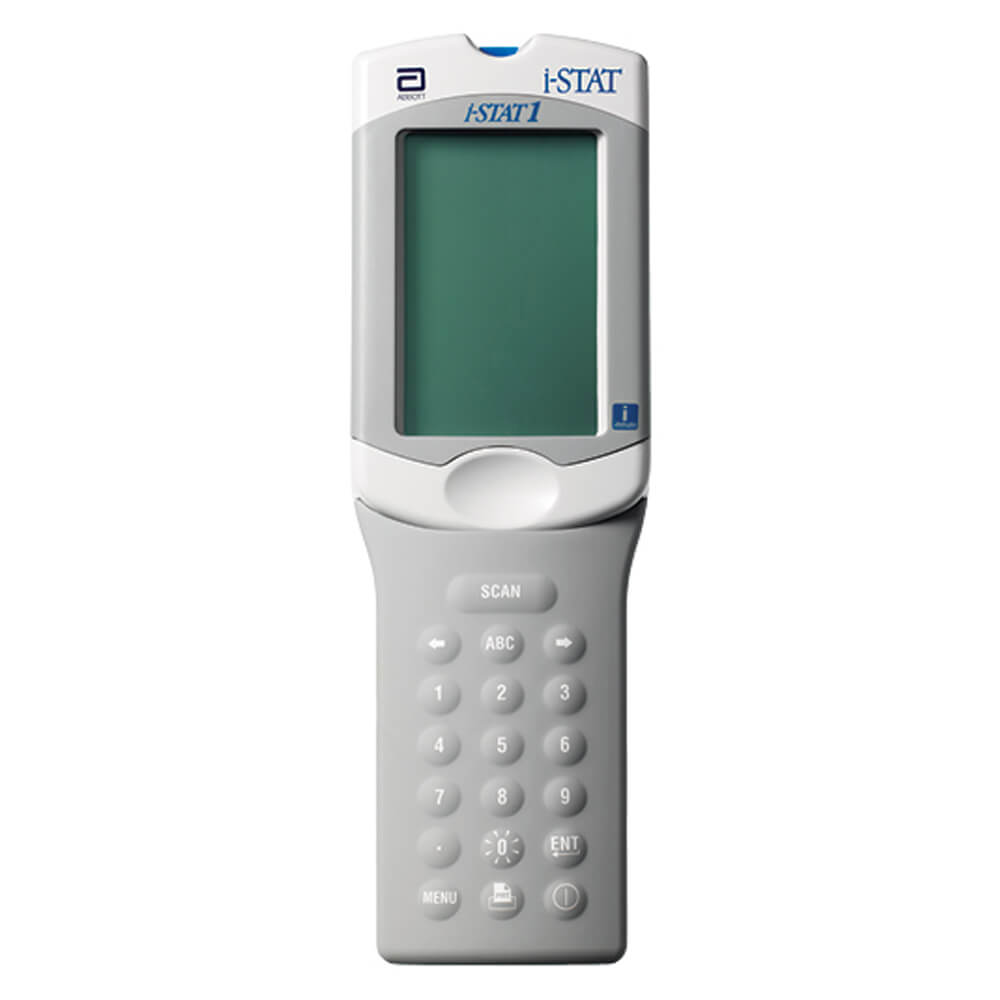

Abbott Handheld Diagnostic Instruments Batteries

Siemens Healthineers Handheld Diagnostic Instruments Batteries

Fujifilm Sonosite Handheld Diagnostic Instruments Batteries

Need to Power a High-Resolution Display and a CPU in a Compact Device?

Our high-density, high-discharge battery solutions deliver the power you need without compromising portability.

Customized Options for Your Handheld Diagnostic Batteries

We engineer every detail for portability, performance, and clinical reliability.

Maximum Energy Density

We utilize the latest cell technologies to achieve the highest possible capacity (mAh) for your device's volume.

Custom Form Factors

We design batteries in unique shapes and slim profiles to fit into ergonomic, handheld enclosures.

Intelligent BMS with Fuel Gauging

We integrate smart BMS with SMBus/I2C communication for accurate, real-time battery status monitoring.

High-Discharge Capability

We can engineer the pack to handle the high peak power demands of processors, screens, and wireless modules.

Fast-Charging Integration

We can design the battery system to be compatible with USB-C PD and other standards for rapid charging.

Robust Housing & Connectors

We use durable, medical-grade materials for the pack enclosure and connectors to withstand daily clinical use.

Get Your Batteries in Bulk, Step-by-Step

In-Depth Consultation & Risk Analysis

We analyze your device's power needs, use case, and regulatory requirements, performing an initial risk assessment.

System Design & DHF Support

We provide a comprehensive proposal with 3D models and can provide documentation to support your Design History File (DHF).

Prototyping & V&V Testing

We produce robust prototypes for your Design Verification and Validation (V&V) testing.

Certification Management & Approval

We manage the entire IEC 62133 and UN38.3 certification process and receive your final approval.

Controlled Mass Production

Your bulk order is manufactured under strict process controls (SPC) and quality checks.

Global Logistics & Lot Traceability

We manage the compliant shipping process, ensuring full lot traceability for every delivery.

FAQ for Handheld Diagnostic Instrument Batteries

A: Our primary strategy is maximizing energy density (mAh per cubic centimeter). We use the most advanced cell materials and custom-shape the battery to fill all available internal space, ensuring the longest possible runtime.

A: Yes, we can design the battery pack with high-discharge-rate (High-C) cells and a robust BMS to handle the high, instantaneous power pulses required by ultrasound transducers and other demanding components.

A: Due to the engineering and validation involved, our MOQ for a new custom medical diagnostic battery typically starts at 50,000 to 100,000 units.

A: Very accurate. We integrate intelligent BMS with fuel gauge ICs that use coulomb counting and communicate via SMBus or I2C. This provides the host device with precise State of Charge (SoC) data, which is critical in a clinical setting.

A: At a minimum, UN38.3 for transportation and IEC 62133 for international safety compliance are required. Depending on your target market, UL or other specific certifications may also be necessary. We manage this entire process for you.

A: Yes, for devices that require continuous operation, we can design a hot-swappable battery system, allowing users to change batteries without powering down the instrument.

A: We use robust materials for the battery pack housing and high-mating-cycle connectors. Our designs are also validated through drop, shock, and vibration testing to ensure they can withstand the rigors of a clinical environment.

A: The lead time for the first batch of prototypes for a new diagnostic device battery is typically 6-8 weeks after design finalization.

A: We provide a comprehensive documentation package, including detailed specifications, manufacturing quality data, and all safety certifications (IEC 62133, UN38.3, etc.) to support your technical file for FDA or CE submissions.

A: Please provide your device’s dimensional constraints (a 3D model is ideal), power requirements (voltage, capacity, peak/continuous current), required certifications, and your estimated annual volume.